|

ELECTRONIC PACKING VENT MONITOR

Analyze your gas compressor packing cases

|

ELECTRONIC PACKING VENT MONITOR

For compressor packing case vent flow analysis

ePV™ is a vent flow analysis tool specifically designed to monitor gas compressor packing cases. The ePV can be permanently mounted or used as a portable device to meet the EPA Greenhouse Gases Reporting Rule Subpart "W" requirements for emissions monitoring.

The ePV™ utilizes proven thermal-dispersion flow measurement technology with equal mass sensing to achieve outstanding sensitivity and repeatability. The instrument’s wetted parts are superior corrosion-resistant 316L stainless steel with Hastelloy-C sensor tips. The sensor element has no moving parts to foul, clog or maintain which ensures continuous reliability and no maintenance costs. There are no cavities, orifices or dead-legs to trap or contaminate samples which preserves sample integrity and faster system sampling times.

ePV™ electronics are packaged in a rugged, fully-sealed, aluminum housing which provides exceptional protection and long-life under all process conditions.

A 4-20mA output can be assigned to flow rate or temperature. The ePV™ unit can be programmed by the sensor push buttons or through the RS232 connection with the provided software.

The ePV™ utilizes proven thermal-dispersion flow measurement technology with equal mass sensing to achieve outstanding sensitivity and repeatability. The instrument’s wetted parts are superior corrosion-resistant 316L stainless steel with Hastelloy-C sensor tips. The sensor element has no moving parts to foul, clog or maintain which ensures continuous reliability and no maintenance costs. There are no cavities, orifices or dead-legs to trap or contaminate samples which preserves sample integrity and faster system sampling times.

ePV™ electronics are packaged in a rugged, fully-sealed, aluminum housing which provides exceptional protection and long-life under all process conditions.

A 4-20mA output can be assigned to flow rate or temperature. The ePV™ unit can be programmed by the sensor push buttons or through the RS232 connection with the provided software.

No moving parts, non-clogging

No moving parts, non-clogging Handles gases and liquids

Handles gases and liquids For use in tubing & piping up to 6" diameter

For use in tubing & piping up to 6" diameter Superior low flow sensing (0-100 FPS)

Superior low flow sensing (0-100 FPS) Single configuration meets all flow ranges

Single configuration meets all flow ranges Outputs include both:

Outputs include both:4-20 mA Analog Output

Serial RS232C I/O

10 LED Array on sensor face

No cavities or dead-legs

No cavities or dead-legs Simple, screw-in installation

Simple, screw-in installation Lowest cost solution for end-users and system integrators

Lowest cost solution for end-users and system integrators Self-contained unit

Self-contained unit Does not require calibration in the field

Does not require calibration in the field

CONTACT US

5440 Alder Dr.Houston, TX 77081

Phone

800-TRY-CECO800-879-2326

713-664-7333

Fax

713-664-6444Email

epvinfo@ceconet.com

www.tryceco.com

® CECO is a registered trademark of Compressor Engineering Corporation.

© 2011 Compressor Engineering Corporation Form 2102 9/11

© 2011 Compressor Engineering Corporation Form 2102 9/11

INSTRUMENT

MEDIA COMPATIBILITY:

All gases and liquids compatible with 316 stainless steel

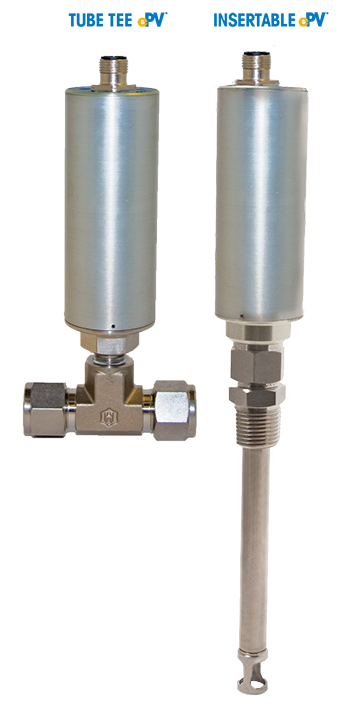

PROCESS CONNECTION:

• Insertable 1/2" NPT• Tube tee 1/4", 3/8" and 1/2" tubing

ACCURACY:

± 1% of reading, ± 0.5% of full scale ± 0.05 SFPS

All calibrations on NIST traceable flow stands

REPEATABILITY:

± 0.5% of readingFLOW RANGE:

From 0 to 100 ft/sec velocity; flow range depends on pipe or tube tee area

OPERATING PRESSURE:

Tube tee ePV: 500 psig

Insertable ePV with compression fitting:

• 150 psig Teflon ferrule

• 500 psig Stainless steel ferrule

OPERATING TEMPERATURE:

Standard: - 40°F to 250°F

MATERIALS OF CONSTRUCTION:

(Wetted parts) 316L stainless steel with Hastelloy C-22 thermowells

TRANSMITTER/ELECTRONICS

ENCLOSURE:

NEMA 4X, anodized aluminum

OPERATING TEMPERATURE:

-40°F to 160°F

OUTPUT SIGNALS

• 4-20 mA (500 Ω max. load) User scalable, general purpose, output proportional flow rate for trend monitoring• RS232C Input/Output Connection

• 10 LED Array

INPUT POWER:

24 Vdc (21.5 Vdc to 30 Vdc); maximum 2.5 watts

AGENCY APPROVALS

FM & FMC/ CE MARK:

Class I, Division 2, Groups A, B, C & D

Class II, Division 2, Groups E, F & G

Class III, T4 @ Ta = 71°C Type 4X

NEMA ENCLOSURE:

Nonincendive

Houston, Texas

800-TRY-CECO • www.tryceco.com