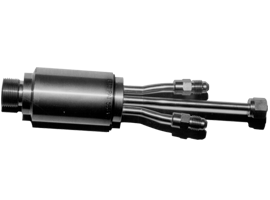

| PRECOMBUSTION CHAMBER CECO has patented a screw-in precombustion chamber that reduces NOx and provides superior ignition enhancement. |

CECO presents the gas pipeline industry's first fully programmable precombustion chamber for natural gas-fired integral gas compressor engines.

CECO Precombustion chambers are the alternative to expensive engine conversions for lean burn operations. On-site modification of your existing equipment eliminates the costly, time-consuming task of shipping engine heads to the original manufacturer for conversion -- or buying new heads altogether.

Our Precombustion chambers ignite the extremely lean air/fuel mixture required for lower emissions, reduces fuel consumption, and increases horsepower. They meet government standards by reducing NO2, HC and CO emissions, assuring the continued operation of your engines even in environmentally sensitive locations.

Each retrofit is custom-engineered and built at our Houston plant to suit your specific engine requirements. Manufactured from high-temperature stainless steel, CECO Precombustion chambers improve service life, maximize performance, eliminate ambient deration, and are designed for easy field installation. Field installed by CECO, Precombustion chambers assure your engines will run lean, clean, and more efficiently on less fuel. They are available for all makes of two-stroke and four-stroke gas engines.

CECO Precombustion chambers are the alternative to expensive engine conversions for lean burn operations. On-site modification of your existing equipment eliminates the costly, time-consuming task of shipping engine heads to the original manufacturer for conversion -- or buying new heads altogether.

Our Precombustion chambers ignite the extremely lean air/fuel mixture required for lower emissions, reduces fuel consumption, and increases horsepower. They meet government standards by reducing NO2, HC and CO emissions, assuring the continued operation of your engines even in environmentally sensitive locations.

Each retrofit is custom-engineered and built at our Houston plant to suit your specific engine requirements. Manufactured from high-temperature stainless steel, CECO Precombustion chambers improve service life, maximize performance, eliminate ambient deration, and are designed for easy field installation. Field installed by CECO, Precombustion chambers assure your engines will run lean, clean, and more efficiently on less fuel. They are available for all makes of two-stroke and four-stroke gas engines.