|

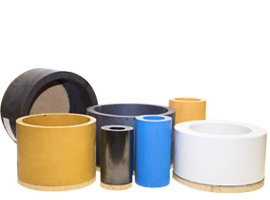

RESILON-T™ MATERIALS

CECO Resilon-T™ materials are the best solution for the most demanding applications.

|

- OVERVIEW

- MATERIALS LIST

- APPLICATIONS

- DOWNLOADS

CECO Polymer Products Division can recommend the best material solution for your application. Download the Grade to Gas Application Bulletin and receive the Resilon-T™ Grade listing, description of each material, and its primary uses.

Selecting the optimal Resilon-T™ material depends on many factors such as pressure, temperature, material of mating surface, corrosive nature of gas being handled, lubrication, and other operating conditions. Several new materials have been added to the CECO Polymer Products Division that are specifically designed for high-speed compressor applications.

Your CECO sales representative is well qualified to assist you in choosing the ring material or combination of materials which best suit the needs of your particular application. Please feel free to discuss service requirements with us at any time. Download and fill in our Ring and Rider or Packing Data Sheets to allow us to recommend the right Resilon-T™ material for your operating conditions.

Selecting the optimal Resilon-T™ material depends on many factors such as pressure, temperature, material of mating surface, corrosive nature of gas being handled, lubrication, and other operating conditions. Several new materials have been added to the CECO Polymer Products Division that are specifically designed for high-speed compressor applications.

Your CECO sales representative is well qualified to assist you in choosing the ring material or combination of materials which best suit the needs of your particular application. Please feel free to discuss service requirements with us at any time. Download and fill in our Ring and Rider or Packing Data Sheets to allow us to recommend the right Resilon-T™ material for your operating conditions.